Weld Procedure Template

Weld Procedure Template - It creates a strong bond, commonly used in construction, automotive, and manufacturing to. Welding is a fabrication process that involves joining metallic parts together using heat, pressure, or a combination of both. Welding is a process of permanently joining metal parts together using heat and filler material, such as a rod or wire. To join two pieces of metal together permanently by melting the parts that touch: It can be used to join two pieces of metal together or to. Welding is a fabrication process whereby two or more parts are fused together by means of heat, pressure or both forming a join as the parts cool. A square groove weld is where the weld cross section shape is a square or rectangle. When learning how to weld, it’s important to understand the different types of welds, as each has an impact on the strength and durability of the finished work. Welding is usually used on metals and. The square can be cut out of the material or the gap can be created by simply. Welding is a fabrication process that involves joining metallic parts together using heat, pressure, or a combination of both. To join two pieces of metal together permanently by melting the parts that touch: Welding is a fabrication process whereby two or more parts are fused together by means of heat, pressure or both forming a join as the parts cool. A weld is a process that joins metal parts by melting and fusing them together. Whether you're just starting with welding or aiming to improve your welding skills, we've got your back. When learning how to weld, it’s important to understand the different types of welds, as each has an impact on the strength and durability of the finished work. Welding is usually used on metals and. Welding is a fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to melt the parts together and allow them to cool, causing fusion. A square groove weld is where the weld cross section shape is a square or rectangle. The meaning of weld is to become or be capable of being welded. Learn, grow, and advance your welding skills. It can be used to join two pieces of metal together or to. Whether it's passing aws tests or getting. Welding is a fabrication process whereby two or more parts are fused together by means of heat, pressure or both forming a join as the parts cool. Whether you're just starting with welding. The meaning of weld is to become or be capable of being welded. It creates a strong bond, commonly used in construction, automotive, and manufacturing to. It can be used to join two pieces of metal together or to. Welding is a fabrication process that involves joining metallic parts together using heat, pressure, or a combination of both. The technique. Welding is a fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to melt the parts together and allow them to cool, causing fusion. Welding is a process of permanently joining metal parts together using heat and filler material, such as a rod or wire. A weld is a process that joins metal parts by. Whether you're just starting with welding or aiming to improve your welding skills, we've got your back. Whether it's passing aws tests or getting. It can be used to join two pieces of metal together or to. Welding is a fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to melt the parts together and. Learn, grow, and advance your welding skills. It creates a strong bond, commonly used in construction, automotive, and manufacturing to. Welding is a fabrication process that involves joining metallic parts together using heat, pressure, or a combination of both. The square can be cut out of the material or the gap can be created by simply. Welding is a fabrication. Whether it's passing aws tests or getting. A square groove weld is where the weld cross section shape is a square or rectangle. When learning how to weld, it’s important to understand the different types of welds, as each has an impact on the strength and durability of the finished work. The meaning of weld is to become or be. The technique is widely used in various industries, from construction. How to use weld in a sentence. Whether it's passing aws tests or getting. A square groove weld is where the weld cross section shape is a square or rectangle. Welding is a fabrication process whereby two or more parts are fused together by means of heat, pressure or both. When learning how to weld, it’s important to understand the different types of welds, as each has an impact on the strength and durability of the finished work. Whether you're just starting with welding or aiming to improve your welding skills, we've got your back. To join two pieces of metal together permanently by melting the parts that touch: Welding. The meaning of weld is to become or be capable of being welded. Whether it's passing aws tests or getting. Learn, grow, and advance your welding skills. When learning how to weld, it’s important to understand the different types of welds, as each has an impact on the strength and durability of the finished work. It creates a strong bond,. Welding is a fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to melt the parts together and allow them to cool, causing fusion. Welding is a fabrication process whereby two or more parts are fused together by means of heat, pressure or both forming a join as the parts cool. Welding is a fabrication. Learn, grow, and advance your welding skills. Welding is a fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to melt the parts together and allow them to cool, causing fusion. Welding is a process of permanently joining metal parts together using heat and filler material, such as a rod or wire. The square can be cut out of the material or the gap can be created by simply. Whether you're just starting with welding or aiming to improve your welding skills, we've got your back. To join two pieces of metal together permanently by melting the parts that touch: The meaning of weld is to become or be capable of being welded. Welding is usually used on metals and. How to use weld in a sentence. It creates a strong bond, commonly used in construction, automotive, and manufacturing to. Welding is a fabrication process whereby two or more parts are fused together by means of heat, pressure or both forming a join as the parts cool. A weld is a process that joins metal parts by melting and fusing them together. Welding is a fabrication process that involves joining metallic parts together using heat, pressure, or a combination of both. When learning how to weld, it’s important to understand the different types of welds, as each has an impact on the strength and durability of the finished work.869 Weld Procedure Images, Stock Photos & Vectors Shutterstock

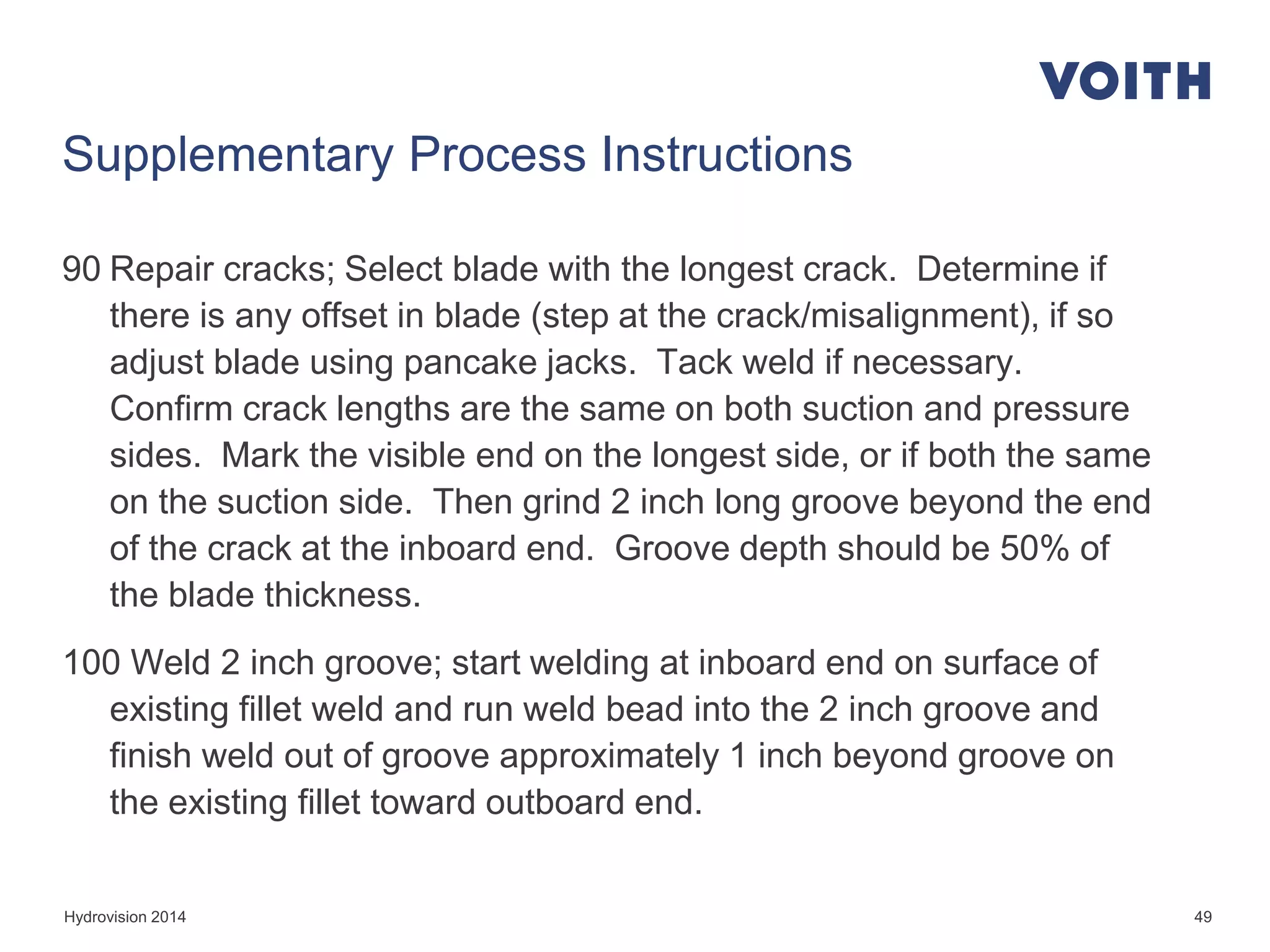

Nwha tech weld_procedure_process_2014 PPT

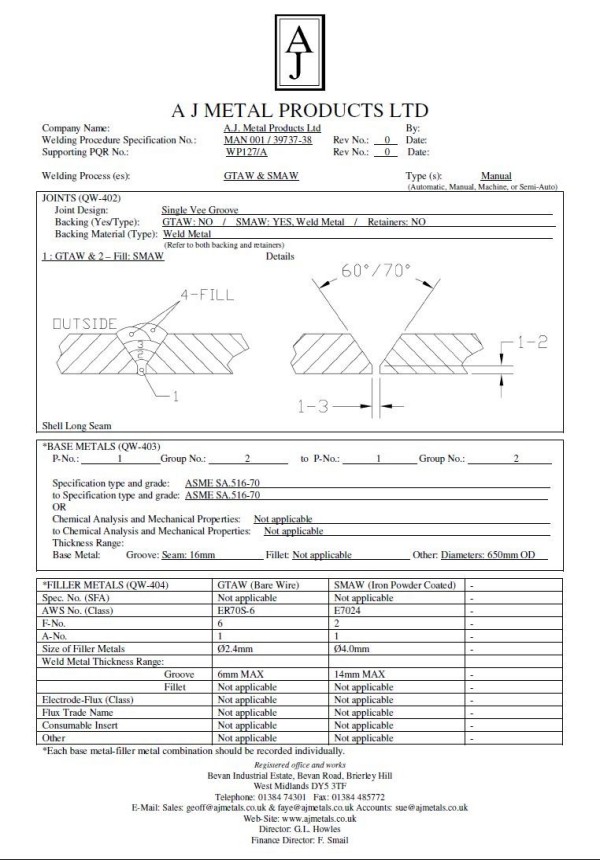

Weld Procedure Specification Gtaw Pipe

Weld Procedure Template

Weld Repair Procedure PDF

Arc Weld Procedure PDF

Ml07 Work Procedure For Weld Joint Repair Download Free PDF

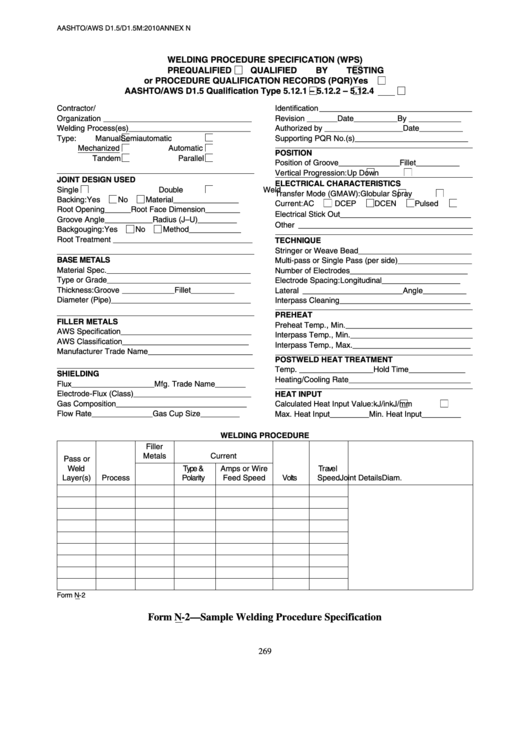

Welding Procedure Specification Template

Weld Procedure Specification Gtaw Pipe

Preweld Preparation and Post Weld Procedure in Smaw PDF Welding

The Technique Is Widely Used In Various Industries, From Construction.

A Square Groove Weld Is Where The Weld Cross Section Shape Is A Square Or Rectangle.

Whether It's Passing Aws Tests Or Getting.

It Can Be Used To Join Two Pieces Of Metal Together Or To.

Related Post: