Haccp Template

Haccp Template - Haccp is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production,. Haccp is an internationally recognized method of identifying and managing food safety related risk and, when central to an active food safety program, can provide your customers, the. Dive into the system ensuring culinary safety. Its definition, significance in food safety, detailed process, and core principles. Hazard analysis and critical control points, or haccp (/ ˈhæsʌp / [1]), is a systematic preventive approach to food safety from biological, chemical, and physical hazards in production. Conducting a hazard analysis, determining critical control points (ccps), establishing critical limits, monitoring ccps, taking corrective. After addressing the five preliminary haccp plan steps and establishing a solid haccp team, the 7 steps of haccp can be fulfilled. Haccp (hazard analysis critical control point) is defined as a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical. Haccp is an important part of food safety management. This guidebook for the preparation of haccp plans presents the foundation of haccp and the seven principles of haccp as set forth by the national advisory committee for the. Its definition, significance in food safety, detailed process, and core principles. Dive into the system ensuring culinary safety. Haccp is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production,. Haccp (hazard analysis critical control point) is defined as a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical. Hazard analysis and critical control points, or haccp (/ ˈhæsʌp / [1]), is a systematic preventive approach to food safety from biological, chemical, and physical hazards in production. Haccp is a systematic preventive approach to food safety. Haccp is based on seven principles: It identifies physical, chemical, and biological hazards in production processes that can cause the finished product to be unsafe. Conducting a hazard analysis, determining critical control points (ccps), establishing critical limits, monitoring ccps, taking corrective. Haccp is an important part of food safety management. Haccp is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production,. Haccp is based on seven principles: This guidebook for the preparation of haccp plans presents the foundation of haccp and the seven principles of haccp as set forth by the national advisory committee for. Dive into the system ensuring culinary safety. Haccp is based on seven principles: Haccp is an important part of food safety management. Haccp (hazard analysis critical control point) is defined as a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical. This guidebook for the preparation of haccp plans presents the. Haccp is an internationally recognized method of identifying and managing food safety related risk and, when central to an active food safety program, can provide your customers, the. Dive into the system ensuring culinary safety. This guidebook for the preparation of haccp plans presents the foundation of haccp and the seven principles of haccp as set forth by the national. Haccp is an internationally recognized method of identifying and managing food safety related risk and, when central to an active food safety program, can provide your customers, the. After addressing the five preliminary haccp plan steps and establishing a solid haccp team, the 7 steps of haccp can be fulfilled. Haccp is a systematic preventive approach to food safety. Its. Haccp is an internationally recognized method of identifying and managing food safety related risk and, when central to an active food safety program, can provide your customers, the. It identifies physical, chemical, and biological hazards in production processes that can cause the finished product to be unsafe. This guidebook for the preparation of haccp plans presents the foundation of haccp. Hazard analysis and critical control points, or haccp (/ ˈhæsʌp / [1]), is a systematic preventive approach to food safety from biological, chemical, and physical hazards in production. After addressing the five preliminary haccp plan steps and establishing a solid haccp team, the 7 steps of haccp can be fulfilled. Under these haccp principles, potential. Its definition, significance in food. Under these haccp principles, potential. Haccp is a systematic preventive approach to food safety. Haccp is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production,. Conducting a hazard analysis, determining critical control points (ccps), establishing critical limits, monitoring ccps, taking corrective. Haccp is an important. Its definition, significance in food safety, detailed process, and core principles. Haccp is an important part of food safety management. Conducting a hazard analysis, determining critical control points (ccps), establishing critical limits, monitoring ccps, taking corrective. Haccp is an internationally recognized method of identifying and managing food safety related risk and, when central to an active food safety program, can. Its definition, significance in food safety, detailed process, and core principles. Under these haccp principles, potential. It identifies physical, chemical, and biological hazards in production processes that can cause the finished product to be unsafe. After addressing the five preliminary haccp plan steps and establishing a solid haccp team, the 7 steps of haccp can be fulfilled. Haccp is an. Conducting a hazard analysis, determining critical control points (ccps), establishing critical limits, monitoring ccps, taking corrective. After addressing the five preliminary haccp plan steps and establishing a solid haccp team, the 7 steps of haccp can be fulfilled. This guidebook for the preparation of haccp plans presents the foundation of haccp and the seven principles of haccp as set forth. After addressing the five preliminary haccp plan steps and establishing a solid haccp team, the 7 steps of haccp can be fulfilled. Haccp is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production,. Haccp is based on seven principles: Haccp is an important part of food safety management. Haccp is a systematic preventive approach to food safety. Hazard analysis and critical control points, or haccp (/ ˈhæsʌp / [1]), is a systematic preventive approach to food safety from biological, chemical, and physical hazards in production. Haccp is an internationally recognized method of identifying and managing food safety related risk and, when central to an active food safety program, can provide your customers, the. This guidebook for the preparation of haccp plans presents the foundation of haccp and the seven principles of haccp as set forth by the national advisory committee for the. Haccp (hazard analysis critical control point) is defined as a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical. Conducting a hazard analysis, determining critical control points (ccps), establishing critical limits, monitoring ccps, taking corrective. Dive into the system ensuring culinary safety.Individual Professional Development Plan Sample New Leadership Deve

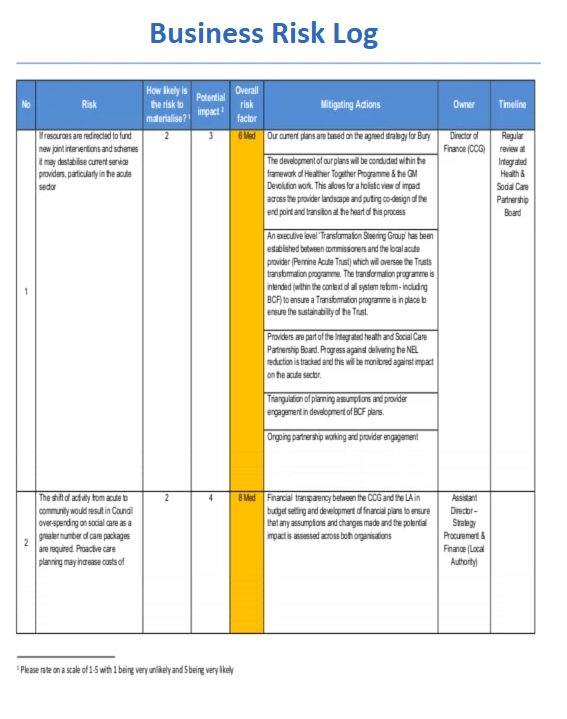

Risk Log Templates 13+ Free Printable Word, Excel & PDF Formats

Free Automotive Design FMEA Example PDF 177KB 9 Page(s) Page 6

FoodDocs HACCP Plan Template PDF

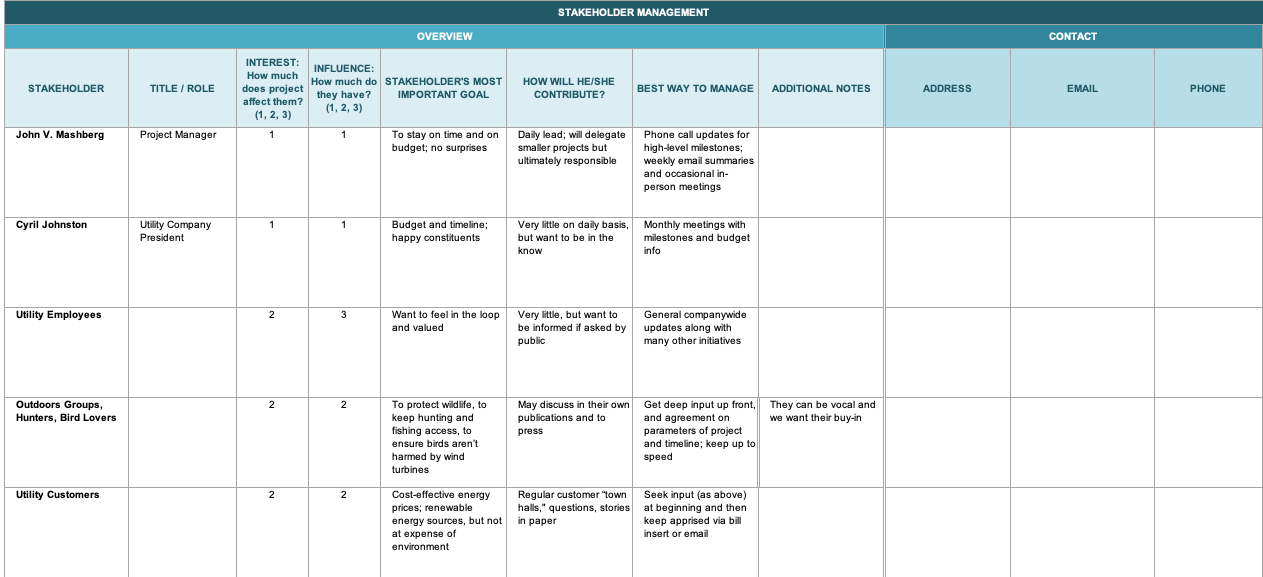

Stakeholder Communication Plan Template Excel

HACCP in a Nutshell

Grass Cutting Job Hazard Analysis template use the free template

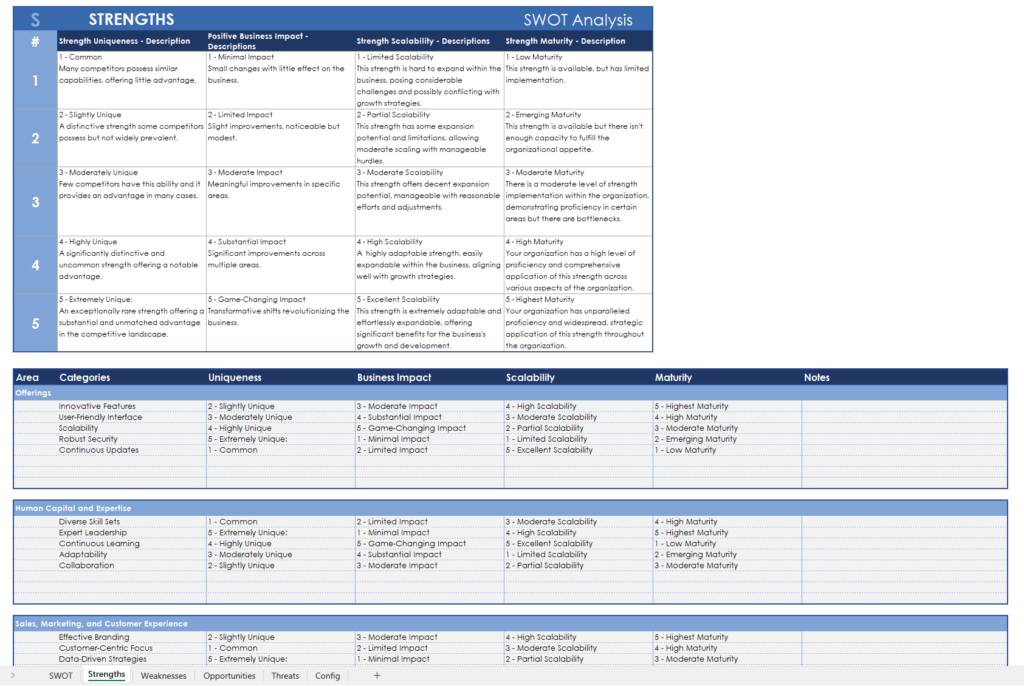

Download the Free SWOT Analysis Template DataCurl Consulting

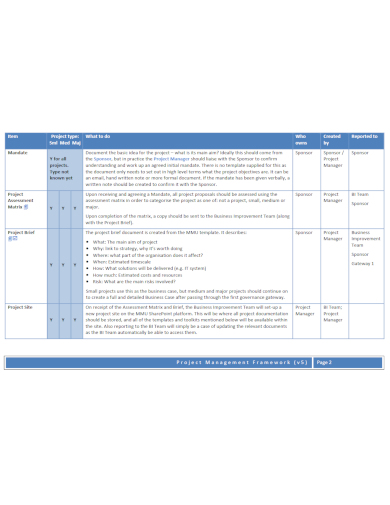

7+ Duties Checklist Templates PDF, Word, Pages, Google Docs

SITXWHS002 Orica Explosives Manufacturing Risk Assessment

Its Definition, Significance In Food Safety, Detailed Process, And Core Principles.

It Identifies Physical, Chemical, And Biological Hazards In Production Processes That Can Cause The Finished Product To Be Unsafe.

Under These Haccp Principles, Potential.

Related Post: