Gemba Walk Checklist Template

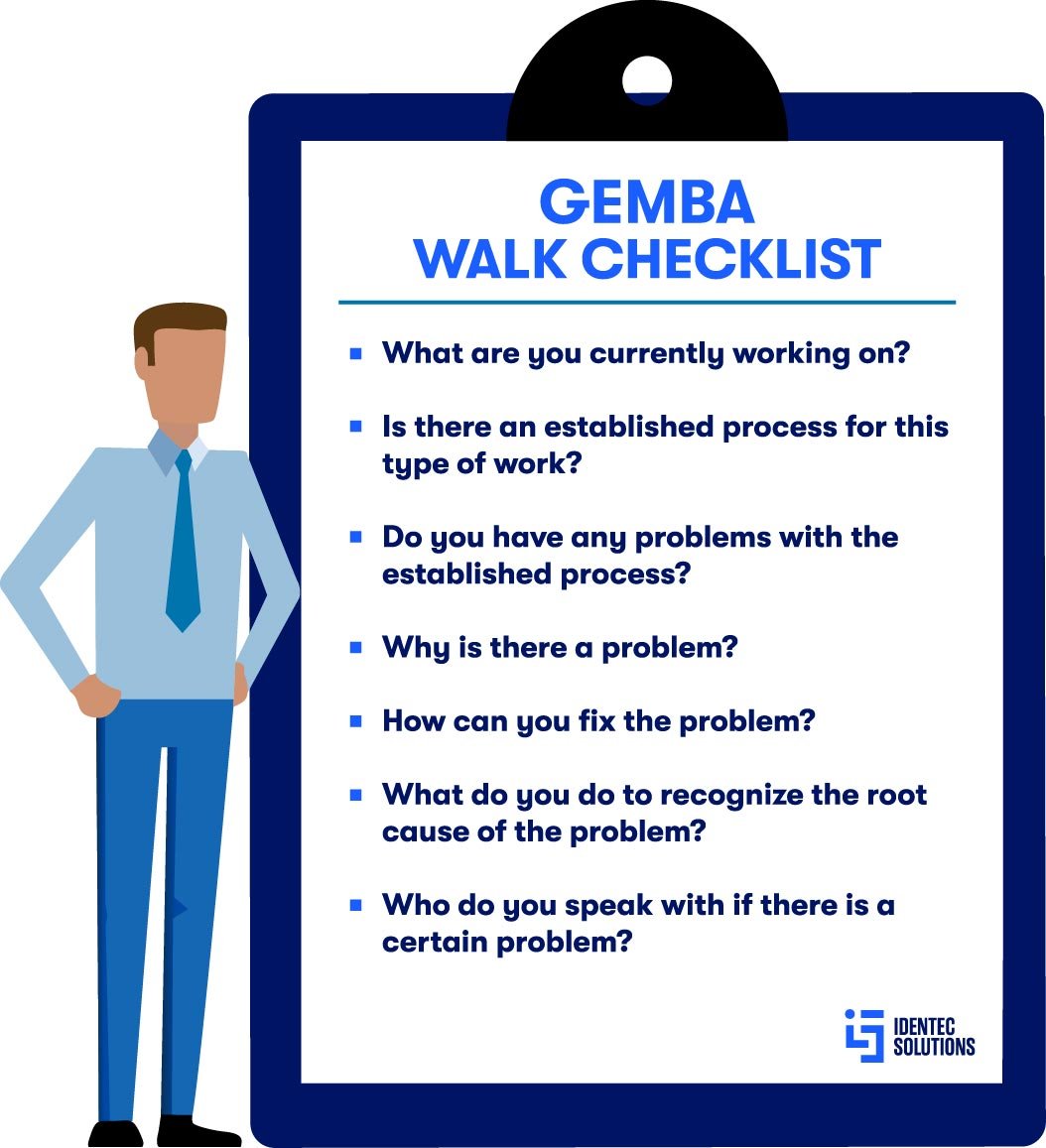

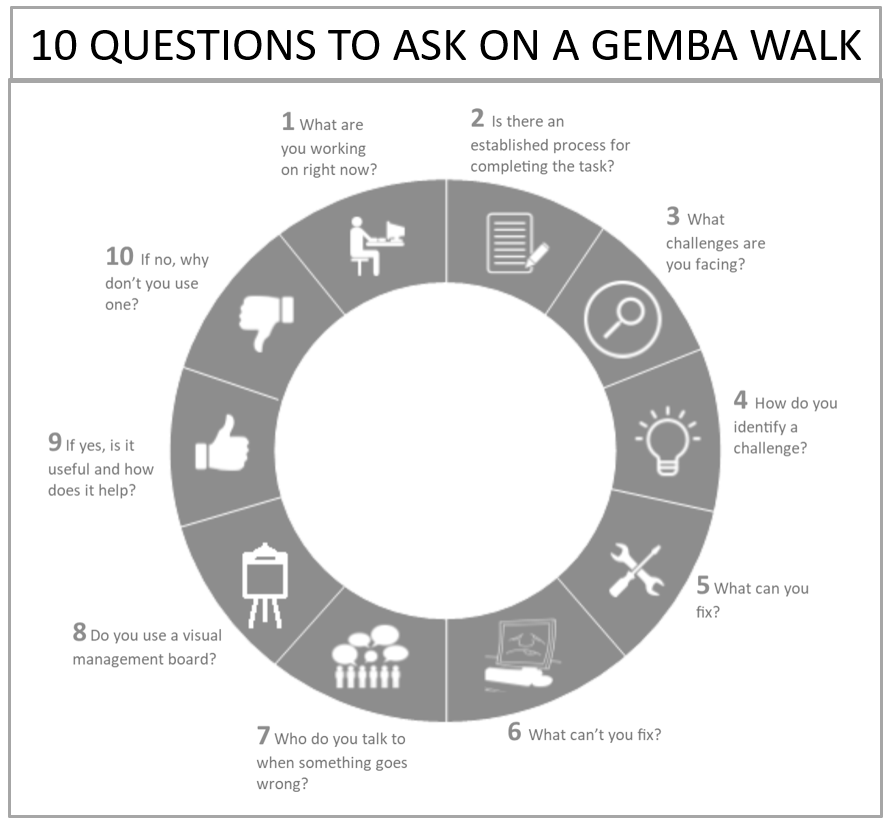

Gemba Walk Checklist Template - It is also spelled genba. Originating from japanese management philosophies, gemba emphasizes the. The gemba walk is a process where employees go to the gemba to see things for themselves and get ideas from the people who are doing the work. Understand its importance in value creation. Literally translated as 'the real place', it pushes the importance of leadership understanding what is happening at. The purpose of a gemba. Gemba is a concept where a manager is expected to be out where the work is being done to observe, solve problems, look for improvement opportunities, and make. A key component of a gemba walk is to get input from employees on what is going right and what is going wrong in a specific operation. Discover the meaning of gemba (現場), the japanese term for the 'real place' in lean and kaizen. Also romanized as gemba) is a japanese term used in business for the location where value is created, such as a factory floor, construction site, or sales floor. Understand its importance in value creation. Gemba is a concept where a manager is expected to be out where the work is being done to observe, solve problems, look for improvement opportunities, and make. Explore the gemba concept in lean management, its origins, and how it drives continuous improvement and operational excellence. Also romanized as gemba) is a japanese term used in business for the location where value is created, such as a factory floor, construction site, or sales floor. Discover the meaning of gemba (現場), the japanese term for the 'real place' in lean and kaizen. Literally translated as 'the real place', it pushes the importance of leadership understanding what is happening at. The gemba walk is a process where employees go to the gemba to see things for themselves and get ideas from the people who are doing the work. In lean practices, the gemba refers to “the place where value is created,” such as the shop floor in manufacturing, the operating room in a hospital, the job site on a construction project, the. It is also spelled genba. 'going to gemba' is the act of visiting the shop floor in lean and kaizen. Explore the gemba concept in lean management, its origins, and how it drives continuous improvement and operational excellence. Gemba is a concept where a manager is expected to be out where the work is being done to observe, solve problems, look for improvement opportunities, and make. Originating from japanese management philosophies, gemba emphasizes the. The purpose of a gemba. Discover. Literally translated as 'the real place', it pushes the importance of leadership understanding what is happening at. Discover the meaning of gemba (現場), the japanese term for the 'real place' in lean and kaizen. Understand its importance in value creation. Gemba, the core of lean principles, represents “the real place” where work happens and value is created. The purpose of. The gemba walk is a process where employees go to the gemba to see things for themselves and get ideas from the people who are doing the work. Literally translated as 'the real place', it pushes the importance of leadership understanding what is happening at. It is also spelled genba. Gemba, the core of lean principles, represents “the real place”. Understand its importance in value creation. The gemba walk is a process where employees go to the gemba to see things for themselves and get ideas from the people who are doing the work. It is also spelled genba. Also romanized as gemba) is a japanese term used in business for the location where value is created, such as a. Explore the gemba concept in lean management, its origins, and how it drives continuous improvement and operational excellence. Gemba is a concept where a manager is expected to be out where the work is being done to observe, solve problems, look for improvement opportunities, and make. Originating from japanese management philosophies, gemba emphasizes the. Also romanized as gemba) is a. Also romanized as gemba) is a japanese term used in business for the location where value is created, such as a factory floor, construction site, or sales floor. It is also spelled genba. A key component of a gemba walk is to get input from employees on what is going right and what is going wrong in a specific operation.. Gemba is a concept where a manager is expected to be out where the work is being done to observe, solve problems, look for improvement opportunities, and make. It is also spelled genba. The gemba walk is a process where employees go to the gemba to see things for themselves and get ideas from the people who are doing the. A key component of a gemba walk is to get input from employees on what is going right and what is going wrong in a specific operation. The gemba walk is a process where employees go to the gemba to see things for themselves and get ideas from the people who are doing the work. Understand its importance in value. The gemba walk is a process where employees go to the gemba to see things for themselves and get ideas from the people who are doing the work. It is also spelled genba. In lean practices, the gemba refers to “the place where value is created,” such as the shop floor in manufacturing, the operating room in a hospital, the. It is also spelled genba. Originating from japanese management philosophies, gemba emphasizes the. A key component of a gemba walk is to get input from employees on what is going right and what is going wrong in a specific operation. Literally translated as 'the real place', it pushes the importance of leadership understanding what is happening at. Explore the gemba. It is also spelled genba. The gemba walk is a process where employees go to the gemba to see things for themselves and get ideas from the people who are doing the work. Originating from japanese management philosophies, gemba emphasizes the. Gemba, the core of lean principles, represents “the real place” where work happens and value is created. The purpose of a gemba. 'going to gemba' is the act of visiting the shop floor in lean and kaizen. Discover the meaning of gemba (現場), the japanese term for the 'real place' in lean and kaizen. Also romanized as gemba) is a japanese term used in business for the location where value is created, such as a factory floor, construction site, or sales floor. Literally translated as 'the real place', it pushes the importance of leadership understanding what is happening at. Gemba is a concept where a manager is expected to be out where the work is being done to observe, solve problems, look for improvement opportunities, and make. A key component of a gemba walk is to get input from employees on what is going right and what is going wrong in a specific operation.Gemba Lean Management

Gemba Lean Management

Master The Art Of Gemba Walks With This Essential Checklist

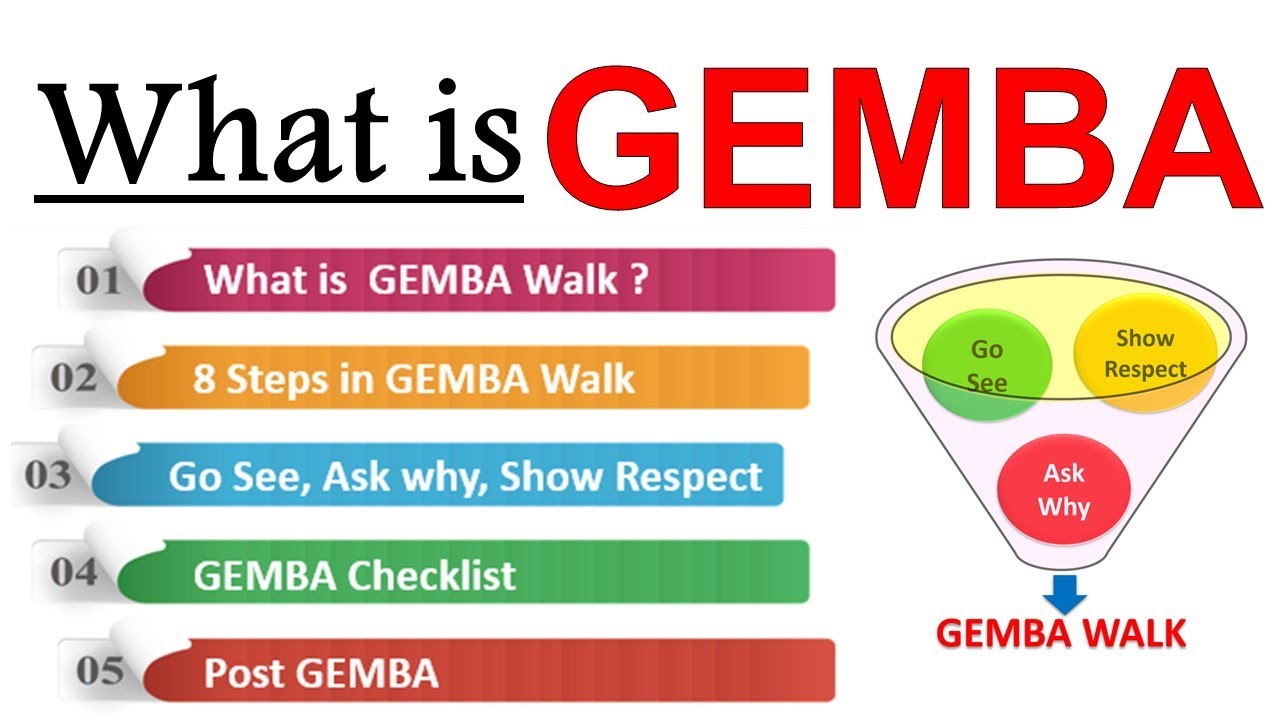

What is Gemba? Gemba Walk in Lean Manufacturing with Steps

Gemba walks a key component of leader standard work Artofit

Gemba Walk How To Do it in 8 Steps and Achieve Great Results?

Gemba Definition, Method, Benefits Explained (Lean Manufacturing

Pin on Lean Six Sigma

Gemba Lean Management

Pasos de aplicación de Gemba Nuestras especialidades Simple Quality

Explore The Gemba Concept In Lean Management, Its Origins, And How It Drives Continuous Improvement And Operational Excellence.

In Lean Practices, The Gemba Refers To “The Place Where Value Is Created,” Such As The Shop Floor In Manufacturing, The Operating Room In A Hospital, The Job Site On A Construction Project, The.

Understand Its Importance In Value Creation.

Related Post: